OpenFOAM for Internal Combustion Engine Simulations, Combustion and Spray

From Ofwiki

Examples of OpenFOAM applications for I.C. engine simulation will be presented in this session, held by Dr. Tommaso Lucchini and Dr. Gianluca Montenegro from the Department of Energetics of Politecnico di Milano. The attention will be mainly focused on the following themes:

- Dynamic mesh motion with topological changes in OpenFOAM

- Spray and combustion modelling

- Coupling OpenFOAM with 1-D codes to simulate the unsteady gas motion in complex intake and exhaust systems

People interested in making a presentation should contact the session organizers by e-mail.

Contributed Presentations

- Introduction by Tommaso Lucchini of Politecnico di Milano Slides

- Automatic Mesh Motion with Topological Changes for Engine Simulation by Tommaso Lucchini of Politecnico di Milano (Part of this work was published in the SAE Congress 2007, paper no. 2007-01-0170). Abstract Slides

- OpenFOAM for LES of premixed combustion and mixing processes by Hannes Kröger, Steffen Jahnke, Nikolai Kornev and Egon Hassel of Universitat Rostock. Abstract Slides

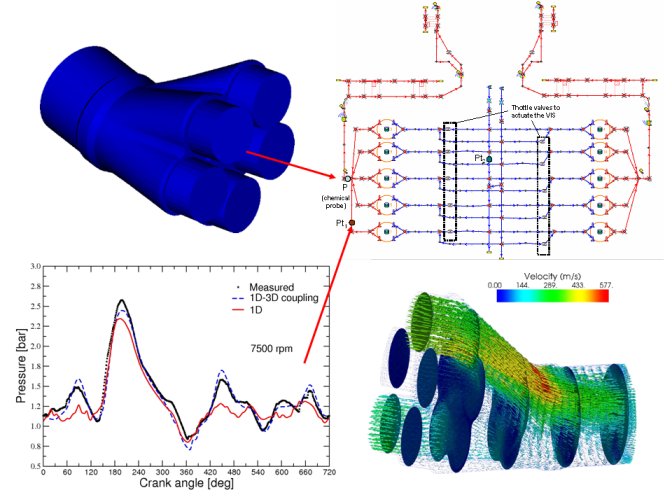

- 1D-3D coupling for Automobile Powertrain Systems by Gianluca Montenegro of Politecnico di Milano (Part of this work was published in SAE Congress 2007, paper no. 2007-01-0935) Abstract Slides

- Multiphase Flow Simulations - Sprays, Cavitation and Hoppers by Fabian Peng Karrholm of Chalmers University of Technology, Goteborg Abstract Slides

- Numerical Simulation of Flashing Flow in Fuel Injector Nozzles Using HRMFoam by David P. Schmidt and S. Gopalakrishnan of University of Massachusetts – Amherst Abstract Slides

Background and Tutorials: Dynamic Mesh Support in OpenFOAM

- Capability talk on Dynamic Mesh Support by Hrvoje Jasak, Wikki Ltd. Capability talk slides

- Automatic Mesh Motion Machinery in OpenFOAM

- Introduction to Topological Mesh Changes in OpenFOAM

- OpenFOAM Tutorial: Engine with Piston and Valve Action by Tommaso Lucchini Tutorial slides

Examples of Engine and Combustion Simulations

1D-3D coupling in an engine and exhaust system

Engine Simulation with Automatic Mesh Motion and Topological Changes

The topological changes implemented in OpenFOAM together with the automatic mesh motion algorithm by Jasak and Tukovic can be used to implement moving mesh algoritms for internal combustion engine simulations.

A new series of engine solvers has been implemented to account for topological changes and mesh motion together with turbulence, combustion and sprays.

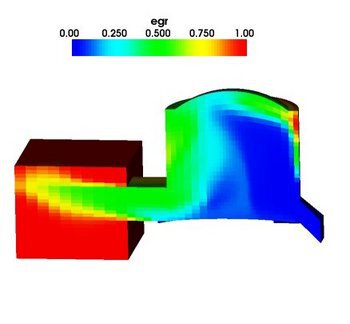

Two Stroke Engine Simulation with Scavenging Ports

The mesh motion for two-stroke engines is performed by combining two different topological changes:

- Dynamic layering for the piston motion;

- Sliding interfaces to dynamically connect the scavenging ports with the cylinder.

The computed EGR distribution is displayed in the picture below.

Four Stroke Engine simulation with moving valves

To be correctly moved, four-stroke engine meshes are decomposed in multiple regions (valve curtains, ports, remainder of the cylinder), which are dynamically connected by a series of sliding interfaces.

Two different modes of motion can be chosed: layering and deformation. During the layering mode, layers of cells are removed by the piston and valve surfaces. During deformation, the cell vertexes are moved by the automatic-mesh motion technique, once imposed the motion boundary conditions.

The valve closure is dealt by the attach-detach boundary mesh modifier, which creates two boundary surfaces from a list of internal faces.

The image below shows the flow and turbulence intensity distribution during the intake stroke in a four-stroke engine with vertical valves.

Simulating Diesel Combustion

Diesel combustion is simulated by using the Lagrangian approach for spray modelling and complex chemistry for combustion. The spray library of OpenFOAM contains different sub-models for:

- spray atomization;

- droplet collision;

- drag;

- heat transfer with the ambient gas;

- wall impingement;

- droplet breakup;

- turbulent dispersion;

- droplet evaporation;

- fuel injection;

Turbulence-chemistry interaction is accounted for by the Chalmers Partially Stirred Reactor concept. Complex chemistry is integrated by a set of ODE solvers. The ISAT (in-situ adaptive tabulation) algorithm has been developed to reduce the computational time required when complex chemistry is used.

The image below displays the combustion process and the spray evolution in a Diesel engine.